Category Archive: Uncategorized

Core drilling employs a hollow punch or drill bit to remove a clean core of material for examination. It’s commonly used in mining, concrete work, and other applications to determine the quality, density, strength, and various other properties of a material. In this post, we’ll look at different types of core drilling, when it should be used, and the bit materials used.

Different Types of Core Drilling

There are two different types of core drilling: soft coring and hard coring.

Soft Coring

Soft coring uses a pair of nested barrels. It’s used for unconsolidated material at depths up to 500 feet, though equipment can go further in the right conditions. The inner barrel pushes out to capture the sample. The outside barrel extends to act as a case, preventing the hole from collapsing. Using this technique protects the core sample from any fluid or air employed when moving the outer barrel to avoid contamination.

Hard Coring

Typically used for collecting competent rock samples, hard coring also uses nested barrels, though the outside barrel extends first in this method. This allows the material to be washed with air or drilling fluid without damaging, disturbing, or contaminating it. This process is sometimes called diamond coring due to the diamond-coated drill bit required to cut stone and rock. It’s used in most substrates harder than sandstone and can easily reach depths of 5,000 feet.

When Should Core Drilling be Used?

When you have a project requiring clear definition of geological formations, coring offers a great option. While mud rotary drilling and other techniquescan provide some subsurface data, they may miss up to a three-inch layer of important material. For projects that have little room for error and a significant price tag, having that data provides the difference between success and failure. Though drilling with a core bit can add more steps to your overall process, gaining a solid understanding of geological formations will save wasted time, resources, and effort.

Core Drilling Materials

For softer materials, it’s common to see carbide-tipped core bits, making it possible for the drill to maintain its edge without compromising the core. With harder materials, stepping up to a diamond-tipped bit allows the integrity of the sample to be maintained through cleaner cuts. Though nickel-bonded electroplated diamond core drill bits work for tile, softer stone, glass, and composite materials, harder materials require more.

Metal-bonded diamond core drill bits are the best option for:

- Sapphire

- Very hard alumina

- Materials with high metal content

- Advanced ceramics

- Natural and precious stones

Though it sounds counterintuitive, you need soft bonds for harder materials to allow drilling to take place in a free, fast fashion. By comparison, softer materials that act in an abrasive rather than cutting fashion will need to have hard bonds to ensure long bit life.

Core Drilling From Kadco Ceramics

At Kadco Ceramics, we employ core drills to create deep holes in very hard materials. Please contact us today to see how we can help with your project.

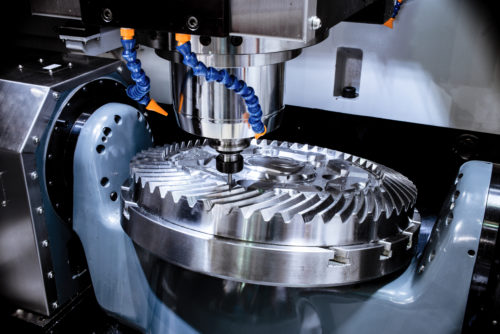

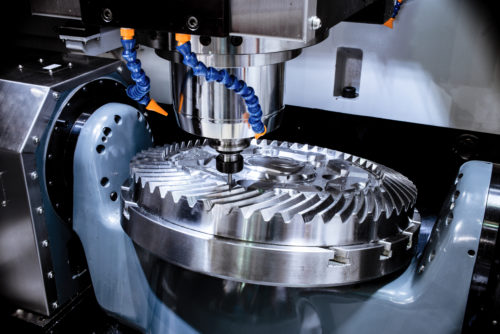

Computer numerical control (CNC) milling is a highly precise subtractive machining process that enables manufacturers to produce high volumes of custom parts quickly and accurately. This process utilizes a combination of programmed computer code and multi-point cutting tools to selectively remove material from a substrate to shape the final part. Since CNC milling machines only need to be programmed once to create large volumes of identical parts, they offer excellent repeatability and are ideal for mass production, particularly in industries requiring high levels of precision.

How Does a CNC Mill Work and What Is a Milling Machine?

CNC milling machines function by affixing the workpiece to a table and shaping it with a cylindrical cutting tool. Guided by the programmed code, the cutting tool moves along multiple axes and creates holes, slots, and other details to create the desired finished product. Most CNC milling machines can accommodate both horizontal and vertical machining operations. Materials suited for CNC machining include:

- Wood

- Plastics

- Metals

- Glass

Unlike other drilling machines, which offer limited cutting angles, CNC milling machines are able to move along three to five different axes. As such, this process enables a high level of detail and precision even at high production speeds. CNC milling machines also require very little manual operation, significantly reducing the risk of human error.

Different Types of CNC Milling Machines

Depending on the specifications of the workpiece, there are several different types of CNC milling machines a manufacturer may use. These include:

Vertical Mill

This versatile type of milling machine moves along three axes. It is composed of a table and an arm, both of which are attached to a vertical column. The vertically oriented spindle is connected to the arm. There are several types of vertical mills such as turret vertical mills, in which the spindle remains stationary while the table moves along the x- and y-axes, and bed vertical mills, in which the spindle moves along the y-axis and the table moves along the x-axis. Regardless of the type of vertical mill, the arm will typically remain stationary while the table moves along the z-axis.

Horizontal Mill

Although they offer slightly less versatility than vertical mills, horizontal mills are ideal for applications involving long or heavy workpieces. These machines differ from vertical mills in that the spindle is horizontal rather than vertical. Additionally, universal horizontal milling machines can move along four axes, as they offer the advantage of rotating the table around the z-axis.

Knee Mill

Knee mills are unique in the method of table movement. With this type of machine, an adjustable knee is necessary to control the table’s movement along the column.

The Importance of CNC Milling

The ability to rapidly mass-produce precision parts is vital across an expansive array of industries. In the past, many machining methods were less efficient and more prone to error, which posed significant risks when producing components for industries such as aerospace and automotive.

However, the rise of CNC milling has made it possible to reduce these risks while simultaneously increasing efficiency. By utilizing computer programs to design and create components, manufacturers are able to take advantage of the speed and accuracy that digital technology provides. In addition to improving the consistent efficacy of the final components, CNC milling also lowers the cost of prototyping.

Kadco Ceramics: Your CNC Milling Experts

At Kadco Ceramics, we offer both three-axis and five-axis milling capabilities at our state-of-the-art facilities. This gives our expert machinists a great deal of flexibility, and enables us to meet the needs of customers across a range of industries. From ceramics and glass to composite structures, we are able to shape virtually any machinable material our customers require. Our diamond tooling technology offers even higher levels of precision, and our in-house design team can provide any assistance necessary to ensure a successful final product.

Since 1982, we have been dedicated to helping our customers find affordable, high-quality solutions for their production requirements. From material selection and design through to manufacturing, we continually prioritize open communication to ensure we meet our customer’s every need. Contact us today to learn more about how we can assist with your next CNC milling project.

Surface grinding machines are used for surface grinding operations. This process removes impurities that can affect the functional and/or aesthetic quality of the final component. It is suitable for use with metallic and non-metallic materials.

How Do Surface Grinding Machines Work?

The three main components of a surface grinding machine are the rotating abrasive wheel, the workholding device, and the reciprocating or rotary table. The abrasive wheel smooths and refines the surface of a material by removing excess material from it. The workholding device (i.e., a chuck) holds the workpiece in place as it is processed. The table moves the workpiece around and across the face of the wheel as needed to achieve the desired specifications.

Types of Surface Grinding Machines

There are three main types of surface grinding machines available, each of which is suitable for different surface grinding applications.

- Horizontal spindle grinders. Horizontal spindle grinders—also referred to as peripheral surface grinders—are engineered to keep the flat periphery of the abrasive wheel in contact with the surface of the workpiece. This setup ensures the creation of a flat shape with a smooth finish, making it ideal for processing components that require flat surfaces. It is also suitable for angled or tapered surfaces and slotted or recessed surfaces. Typical components made using these machines include connecting rods, pins, and pistons.

- Vertical spindle grinders. Vertical spindle grinders—also referred to as wheel-face surface grinders—are designed for the quick removal of excess material from the workpiece. The abrasive wheel can be made in various forms to accommodate different component shapes. Typical components made using these machines include gears, rotors, and spacers.

- Single-disc/double-disc grinders. Single-disc and double-disc grinders are available in horizontal and vertical configurations. Single-disc grinders allow for a larger area of contact between the abrasive wheel and the workpiece, while double-disc grinders enable both sides of the workpiece to be processed at the same time. Typical components made using these machines include gears, plates, and washers.

Surface Grinding Services at Kadco Ceramics

Does your project involve surface grinding ceramic materials? The experts at Kadco Ceramics are here to help! Equipped with extensive ceramic surface grinding experience, we have the knowledge and skills to achieve the finish you need every single time. We offer a range of capabilities, including:

- Centerless end grinding

- Rotary grinding

- Grinding fixtures

To learn more about our surface grinding offerings or discuss your specs with one of our team members, contact us today.

Pressure transducers—also known as pressure sensors or transmitters—are devices engineered to measure and display the pressure of fluid within a system. They play a vital role in many pieces of equipment that require precise pressure measurement to work effectively and/or efficiently, including aircraft, HVAC systems, and pumps.

How Do Pressure Transducers Work?

These devices work by converting pressure into analog electrical signals. They first measure the pressure of the fluid using a force collector (e.g., a flexible diaphragm that deforms when it is pressurized). This pressure measurement is then converted into an electrical output signal by a transduction element that uses a dependent resistive, capacitive, or inductive mechanism (e.g., a strain gage). Since the signal generated is proportional to the pressure, relaying it to controllers or programmable logic controllers (PLCs) enables trained facility workers to evaluate if the pressure is within an acceptable range.

There are many types of pressure transducers available. While basic models use strain gauges to measure the pressure acting upon them, advanced models use capacitance or piezoelectric sensors, which offer broader range, greater environmental suitability, and better precision.

Creating Pressure Transducers Using Precision Dicing and Machining

Piezoelectric pressure transducers convert applied pressures to electrical signals using components made from quartz, ceramic, or other similar materials. The pieces must be carefully manufactured to work as intended. That’s why many industry professionals to the machining experts at Kadco Ceramics. We have the knowledge, skills, and tools to handle piezoelectrical materials and turn them into precision components, such as pressure transducers.

Our piezoelectrical materials list includes:

- Berlinite

- Cane sugar

- Quartz

- Rochelle salt

- Topaz

- Tourmaline

Our machining capabilities include:

- Wafer dicing: a process used to separate small pieces of material—i.e., dice—from a semiconductor wafer

- CNC milling: a process that utilizes computerized machines and tools to create the desired components by removing excess material from the workpiece

- Core drilling: a process that removes a cylindrical core from the drilled hole

- ID slicing: a process that produces repeated cuts on hard, brittle material

- Surface grinding: a process that uses an abrasive disc or wheel to smooth and refine the surface of a material

Kadco Ceramics: Your Partner and Expert for Piezoelectric Pressure Transducers

Need piezoelectric pressure transducers? The piezoelectric machining experts at Kadco Ceramics are here to help! Our precision dicing and machining capabilities enable us to handle virtually any hard or soft material and turn it into a range of precision end products, including pressure transducers. To discuss your product specs with one of our representatives, contact us today.

What Is CNC Drilling?

CNC drilling is a machining process that utilizes a rotating cutting tool to produce round holes in a stationary workpiece. The holes are typically made to accommodate machine screws or bolts for assembly purposes. However, they can be used for aesthetic purposes depending on the design of the component.

How Does CNC Drilling Work?

The CNC drilling process has similar steps to many of the other CNC machining operations. These include:

- Creating the component design in CAD software. The first step in producing a CNC drilled component is creating a digital design of it in CAD software.

- Converting the design into machine instructions. Once the component design is finalized, it needs to be converted into a language the CNC unit can understand. This step typically requires running the CAD design through CAM software to generate machine code.

- Loading the instructions to the CNC machine. When loaded to the CNC machine, the machine code controls how the CNC machine and tooling will move and operate throughout the drilling process.

- Setting up the CNC machine. Setting up the CNC machine generally involves installing the appropriate drill bit and securing the workpiece.

- Executing the drilling operation. Once the machine code is loaded and the machine is set up, the operator can initiate the drilling operation.

- Evaluating the component. After the drilling operation is finished, the operator evaluates the component for any errors or imperfections.

Advantages of CNC Drilling

Compared to traditional drilling technologies, CNC drilling units offer a number of advantages, such as:

- Higher accuracy. Drilling machines integrated with CNC technology can make holes that are accurate to t

he original design file within very tight margins.

he original design file within very tight margins.

- Broader versatility. CNC drilling units can be used for a wide range of materials, from metal to plastic to wood. Additionally, since they can accommodate multiple drill bits, they can be utilized to produce a variety of holes.

- Greater reproducibility. Since CNC drilling units are computer-controlled, they are lessprone to error. As a result, manufacturers can achieve high consistency throughout a batch and between batches.

Kadco Ceramics: Your CNC Drilling Experts

Want to learn more about CNC drilling? Contact the machining experts at Kadco Ceramics! Equipped with over 30 years of experience in the machining industry, we’re well-equipped to answer or address any questions or concerns you may have.

Ferroelectric and piezoelectric materials each have a wide range of applications across multiple industries. These crystalline materials exhibit distinct electrical and structural properties that

Ferroelectric materials exhibit spontaneous nonlinear polarization in the absence of an electric field. This polarization can be reversed by exposing the material to a strong electric field, after which the polarization will maintain its direction until a reverse electric field is applied to change it again. Some common examples of ferroelectric materials include PVF2, liquid crystals, and PZT thin films. Ferroelectric materials see frequent use for electronic components, such as capacitors, actuators, sensors, computer memory, and more.

Though all ferroelectric materials are also piezoelectric, not all piezoelectric materials are ferroelectric. A piezoelectric material converts mechanical energy into electric energy. When piezoelectric materials are subjected to physical stress, such as stretching, bending, or compression, they develop electric potential as charge domains within the material get rearranged. An inverse effect occurs as well—piezoelectric materials exposed to an external electric field will change shape.

Piezoelectric Machining at Kadco Ceramics

Piezoelectric materials are used in a wide range of household and industrial devices. While some piezoelectric materials develop naturally, such as topaz and quartz, synthetic ferroelectric ceramics are often more cost-effective and provide better piezoelectric properties. These benefits have made piezoelectric ceramics very popular for equipment ranging from inkjet printers to generators.

It is vital to ensure that you are working with a vendor who will select the right ceramic material and shape it to meet your specifications. At Kadco Ceramics, we can help you choose the appropriate piezoelectric ceramics for your application. We also offer machining services for both prototyping and production.

With our piezoelectric machining capabilities, we can produce the complex geometries required for applications like ultrasonic submarine detection and non-invasive neurological surgeries. We also work with other hard materials, including:

- Alumina

- Ferrites

- Glass

- Quartz

- Sapphire

- Silicon

- Zirconia

We are always eager for opportunities to work with new and unusual materials.

Your Piezoelectric Machining Experts

Machining piezoelectric materials requires specialized equipment and knowledge. At Kadco Ceramics, we combine state-of-the-art machinery with proprietary techniques and experience to machine piezoelectric materials for complex applications. Our expert staff gets precision results, no matter how difficult the material.

Get in touch today to learn more about how we can serve your piezoelectric material needs.

The Piezoelectric crystal is used in a broad variety of common consumer, commercial, and industrial products. These crystals are used in watches, ultrasound equipment, microphones, cigarette lighters, inkjet printers, speakers, and a wide variety of sensors and motors, among many other applications.

What is a Piezoelectric Crystal?

Piezoelectric crystals are capable of the piezoelectric effect, which is the ability of a material to generate an electric charge when subjected to pressure. There are both natural and synthetic materials with this potential.

This effect was discovered in 1880 by Pierre and Jacques Curie, although it didn’t have any practical applications outside of the laboratory for many years. By World War I, it was used in the creation of sonar, which sparked interest in the potential for further technological advances using the piezoelectric effect.

How Do Piezoelectric Crystals Work?

The potential to conduct electricity is a result of the material’s structure. Piezoelectric crystals have a balanced charge with an asymmetric atomic structure. When mechanical pressure is applied, the structure is deformed, pushing the negative charge to one side and the positive charge to the other. This is known as the direct piezoelectric effect. Crystals with symmetric structure aren’t impacted by pressure in this way and are not piezoelectric.

This effect works in reverse as well—passing electricity from an external source through piezoelectric crystals will convert the electrical energy into sound waves. This is what was used to create sonar, and it is called the inverse piezoelectric effect.

How to Generate Electricity from Piezoelectric Crystals

The process is simple for generating electricity from a piezoelectric crystal that is fairly simple. To turn mechanical energy into electrical energy (the direct piezoelectric effect), metal plates are used to squeeze the crystal. The pressure disturbs the atomic structure and creates an electrical charge which is collected by the plates. More pressure means more electrical power.

The inverse piezoelectric effect is created when the balanced crystal, again placed between two metal plates, is charged with electricity. This essentially forces the crystal to squeeze itself, deforming its structure, which releases a sound wave.

Which Type of Crystals/Materials Exhibit Piezoelectricity?

Quartz is probably the most well-known piezoelectric crystal, perhaps because of its use in quartz clocks and watches. However, there are other materials (crystals and others) with this quality found in nature:

- Topaz

- Tourmaline

- Rochelle salt

- Tourmaline

- Bone

- Enamel

- Collagen

- DNA

Synthetic piezoelectric materials are typically more cost-effective than naturally occurring ones, so manufactured materials like langasite, lithium niobate, barium titanate, potassium niobate, sodium tungstate, lead zirconate titanate (PZT), and others are often used instead of natural crystals. These synthetic options also tend to have stronger piezoelectric potential.

Piezoelectric Materials at Kadco Ceramics

At Kadco Ceramics, we have a great deal of experience machining a wide variety of piezoelectric materials for everything from sonar to medical equipment, and we can help you choose the piezoelectric material that would best suit your application. In some cases, quartz or topaz may be ideal, or it may be better to use synthetic ferroelectric ceramics for their stronger piezoelectric effect and cost-effectiveness. We’re happy to discuss your project and help you determine the best option.

Contact us to learn more about piezoelectric materials and our machining capabilities.

Wafer Dicing

Dicing is commonly used to separate optical components or electronics imaged onto wafers. The substrates can be waxed onto hard mounts to minimize chipping.

Experienced dicing experts are able to make precise cuts and grooves and optically align microscopic patterns.

What is Wafer Dicing?

The wafer dicing process separates small blocks of semiconducting material (known as dice) from a semiconductor wafer. Depending on the application’s needs, the dicing process may involve wafer scribing, through cutting, or wax mounting. The wafer is sawed in the extra spaces between dice to separate them.

The wafer dicing process separates small blocks of semiconducting material (known as dice) from a semiconductor wafer. Depending on the application’s needs, the dicing process may involve wafer scribing, through cutting, or wax mounting. The wafer is sawed in the extra spaces between dice to separate them.

Usually, manufacturers mount wafers onto tape to improve their backside support. Once the wafer has been mounted, it’s loaded into a cassette and then into the actual dicing mechanism, which cuts the wafer into individual dice.

The dicing mechanism contains an abrasive blade that it rotates with a spindle at high speeds (usually 30,000–60,000 rpm).

Blades used for this purpose comprise diamond grit embedded into an electroplated nickel matrix. Because these blades are so strong, they easily crush wafers, and any debris that it creates can be removed while the machine works.

The blade moves between active areas of the dice through dedicated lines known as streets. This creates a groove in the substrate material.

Wafer Dicing Techniques

Wafer Scribing

The term “scribing” refers to a specific die singulation technique. This technique uses only one process tool to partially cut through a wafer. Then, a breaking step divides the wafer into individual dice along scribed lines. This separates scribing from the more traditional option of dicing, which involves cutting through a wafer entirely in just one step.

Through Cutting

When wafers are through cut on tape, it’s easy to achieve higher tolerances on the final chip size. The primary drawback of this process is that it can result in some bottom-side chipping. Some manufacturers get around this by wax mounting wafers onto glass to offer more precise cuts.

Wax Mounting

Wax mounting on glass is labor intensive, but doing so often leads to superior quality. Before the process can begin, manufacturers must clean the workpieces, which helps achieve the best possible edge quality. When substrates are wax mounted on glass, the superior bottom-side support results in fewer instances of chipping. Sometimes tape mounting is used for a simpler process.

Wafer Dicing Services at Kadco Ceramics

Dicing work involves quartz, alumina, piezoceramics, glass, and layered combinations of materials. Our work involves not only die singulations on wafers but also cutting grooves and forming surface features.

Our staff uses multiple Disco and K&S dicing machines to meet our clients’ wafer dicing needs. Our certified team of engineers is dedicated to understanding the individual needs of each client—they’ll speak with you about your goals, the tradeoffs you may make to reach them, and any other requirements you’re working with.

If you would like to learn more about Kadco Ceramics’ wafer dicing services, contact us today.

Computer numerical control (CNC) milling is a machining process that uses rotating multipoint cutting tools and computerized controls to cut and shape workpieces into custom-designed components.

Manufacturers use CNC milling to produce a wide range of products from materials ranging from:

In contrast with traditional drilling equipment, CNC milling machines operate along multiple axes, allowing for the creation of a wide variety of shapes, slots, holes, and other impressions required for the specific end application.

How Does the CNC Milling Process Work?

The CNC milling process conforms to the same basic stages of production as other machining processes. These stages include:

- CAD model design

- Conversion of the CAD model into a CNC program

- CNC milling machine setup

- Execution of the milling operation

The initial CAD design for the desired product can be rendered in either 2D or 3D. Upon completion of the design, engineers transfer it to a CNC-compatible file. CAM software converts this file into a CNC machine program that will control the milling machine’s subsequent movements and actions.

Next, the CNC machine operator prepares the milling machine to execute the program. The appropriate milling tools are attached to the machine’s spindle, and the workpiece is either affixed to an attached worktable or a vise. The choice between worktable and vise depends on whether the workpiece will remain stationary during the milling operation or slowly be fed into the rotating tool.

When the milling operation begins, the CNC cutting tool reaches speeds as high as thousands of rotations per minute. During operation, the CNC machine will perform one of these three cutting methods:

- Slowly feed the material into the rotating tool as it remains fixed in place

- Move the rotating tool over and across the stationary target material

- Use a combination of the above two methods by moving both the target material and the rotating tool in relation to each other

Additionally, milling equipment operates via one of two methods:

- Climb milling, in which the CNC machine feeds the target material with the rotation of the cutting tool

- Conventional milling, in which the material is fed against the tool’s rotation

Operators frequently run the target material through the CNC machine multiple times to ensure that it meets specified tolerances. After completing the milling operations, the product is ready for finishing and post-processing.

CNC Milling Machines

Milling machines typically come in either horizontal or vertical forms. Horizontal milling equipment uses horizontally oriented spindles, and vertical milling equipment uses vertically oriented spindles.

The shape, size, and weight of the target workpiece along with its desired result play a large role in determining which type of milling machine would be more effective for a particular operation.

For instance, horizontal milling machines are usually more effective at cutting heavy workpieces, whereas vertical milling machines are ideal for those involving complex designs.

Some common types of CNC milling machines include the following:

Knee-type

These types of milling machines use fixed spindles mounted on vertically adjustable worktables. The machine’s “knee” supports its “saddle,” which in turn supports the worktable.

The machine’s knee is attached to the main column. The knee can be lowered and raised depending on the rotating tool’s position. This CNC machine category includes floor-mounted and bench-type plain horizontal milling machines.

Ram-type

Ram-type milling machines have a movable housing, or “ram,” attached to the main column. The machine spindle attaches to this adjustable housing. This allows the machine tool to enjoy the freedom of movement along the x and y-axes.

Floor-mounted universal horizontal and swivel cutter head milling machines are two very common examples of this type of CNC machine.

Bed-type

In this type of milling machine, worktables are affixed directly to the machine bed, which stabilizes the workpiece and prevents undesirable movement along the y and z axes. The operator positions the workpiece beneath the cutting tool, which is often capable of moving along all three main directional axes (x, y, and z).

Some bed-type milling machines include simplex, duplex, and triplex milling machines. One main difference between these three machines is the number of spindles they employ: simplex machines use one spindle, duplex machines use two, and triplex machines use three.

Planer-type

Planer-type milling machines are comparable with bed-type machines in that they have worktables fixed along the y and z-axes.

They also have spindles that can move along all three of the main directional axes. Planer-type machines offer simultaneous support for multiple machine tools (typically as many as four).

This can greatly reduce the turnaround time for the production of complex parts.

Best Materials for CNC Milling

CNC milling is a versatile manufacturing process that encompasses the use of a variety of materials. The best material to use for a specific order depends on the desired end application of the product.

Some of the harder materials suitable for CNC milling include:

- Alumina: Alumina comes in different varieties. Producers use 99.6% alumina for thin-film microwave circuits that operate at higher frequencies. 92% alumina is effective for packaging applications.

- Garnet: Garnets are extremely hard metal silicates. They see use in the electronics and optics fields.

- LiNbO3: LiNbO3 is a dense synthetic crystal used for photonics applications.

- Tungsten: Tungsten is a hard metal that works well in electronic applications.

What Is Core Drilling?

Core drills remove cylindrical cores from targeted areas on a workpiece. Depending on the desired application, the end product could be the newly hollow material or the core itself.

Examples of core drilling machines include machines used for mineral exploration as well as construction core drills that create holes for pipes and manholes.

CNC Milling Service and Core Drilling at Kadco Ceramics

Kadco Ceramics has years of experience in the CNC milling and core drilling industry. We apply our vast expertise to the detailed, precise shaping of just about any machinable hard material. Our experienced machine operators use precision milling equipment to produce complicated, highly customized shapes to client specifications within quick turnaround times.

If you’d like to learn more about how our CNC milling and core drilling services can benefit your company, contact us today for more information.

Ceramics can be made from several different types of hard metal oxides or nitrides. Additionally, materials like silicon carbide (SiC) may not fit the precise definition of a ceramic material, but they can still be classified as part of the ceramic “family.”

Manufacturers use ceramic machining to produce a wide range of mechanical, electrical, and optical appliances. To prepare for the machining process, operators wax mount ceramic substrates onto glass surfaces. Then, operators use manufacturing equipment to cut the ceramic material with focused streams of pressurized water flowing through diamond blades.

Kadco Ceramics performs a variety of ceramic machining operations, such as:

- CNC Milling

- Core drilling

- Wafer dicing

- ID slicing

- Surface grinding

- Piezoelectric machining

Our experienced machinists ensure that Kadco delivers high-quality work that meets or exceeds client specifications.

CNC Milling and Core Drilling

Two common machining services that Kadco offers are CNC milling and core drilling.

CNC Milling

CNC milling stands for computer numerical control milling. Milling is very similar to drilling and cutting, and CNC milling machines perform both of these operations at a variety of angles.

CNC milling is a highly customizable automated machining process. Equipment used for this technique rely on computerized controls and specialized cutting tools to create the desired product by progressively removing material from the workpiece.

How does a CNC milling machine work? The milling process moves through the same four production stages as other machining models. These stages are:

- The design of a CAD (computer-aided design) model for the product

- The CAD model’s conversion into a CNC program

- Setup of the CNC milling machine for operation

- Execution of the milling operation

CNC milling machines may be either horizontally or vertically oriented depending on the nature of the cutting operations as well as the properties of the target material. The milling machine’s rotating multipoint (or “multi-tooth”) cutting tools perform the desired milling operations according to the instructions from the CNC program.

Milling operations in which the machine feeds the target material along with the rotation of the cutting tool are known as climb milling processes. In contrast, milling operations that feed the moveable workpiece against the tool’s rotation are referred to as conventional milling processes.

Upon completion of the milling operations, the product passes over to finishing and post-processing operations.

Core Drilling

Core drilling removes a cylindrical core from the drill hole. A core drill comprises three main parts:

- motor

- handle

- drill bit or bits

The drill bit(s) are typically coated with either diamond or carbide. Core drills used for concrete generally have diamond-coated drill bits, whereas masonry core drills use carbide-coated bits.

Many types of core drills are in use today. These range from small core drills used by homeowners for DIY projects to huge core drills that cut concrete on big construction projects.

Core drilling allows for the clean removal and analysis of a core of the material. In other applications, where the desired outcome is simply the formation of a hole, the core is discarded.

Wafer Dicing

Wafer dicing is a machining process that separates dice from a wafer of semiconducting material. This separation is accomplished through scribing and breaking, mechanical sawing, or laser-cutting operations. Upon completion of the dicing process, leftover individual silicon chips are encapsulated in chip carriers and are subsequently used in a variety of electronic applications.

Wafers can generally be tape mounted on a film frame for ease of handling. Alternatively, the wafers can be wax mounted on the glass to increase cutting precision. Kadco Ceramics performs several types of wafer dicing operations, including:

- Bevel cutting: This cutting process creates a V-shaped groove or chamfer in the target substrate.

- Burr control: Combinations of machining tools and speeds can mitigate the burr formed on the target material’s cut edge.

- Chip control: Kadco operators carefully monitor factors such as feed, speed, and coolant flow to ensure that edge chipping levels remain well within specifications.

- Scribing: Scribing, or marking the wafer, can assist in subsequent breaking operations.

- Wraparound metallization: Wraparound metallization provides good grounding properties in microwave circuits.

- Cleaning and packaging: Upon completion of dicing operations, thorough die cleaning ensures that the finalized product is in pristine condition and ready for packaging. In some processes, the target substrate can be coated with a protective layer before dicing begins.

Inner or internal diameter (ID) slicing operations are an extremely effective way to create repeated cuts on hard, brittle materials. ID slicing saws provide enhanced accuracy.

The ID slicing saw blade is composed of an annular (ring-shaped) apparatus with a diamond-plated internal diameter. This configuration allows for the machine to perform highly precise cutting operations with minimal kerf loss. ID slicing operations are effective for materials as diverse as:

- Silicon

- Piezoceramics

- Ferrites

- Quartz

ID slicing operations typically do not require extensive setup procedures, and they’re usually easy to program. This ease of use often makes ID slicing more cost effective than other methods such as outer diameter slicing or wire sawing.

Surface grinding is a common refining and smoothing process. In this process, a grinding wheel or disc removes the roughness from the target material’s surface, and then it refines the workpiece’s surface and edges too tight tolerances.

There are three basic types of surface grinders:

- Grinders with horizontal spindles: In these grinding operations, the flat edge of the grinding wheel contacts the workpiece, leading to high-precision results.

- Grinders with vertical spindles: In contrast with horizontal spindle grinders, vertical spindle or wheel-face grinders remove large amounts of material at a time. The face of the grinding wheel, instead of its edge, comes into contact with the targeted surface.

- Single- or double-disc grinders: Disc grinders can be horizontally or vertically aligned, and they often can grind two sides of the workpiece at the same time.

Piezoelectric materials can generate electrical charges when placed under mechanical tension or pressure. Examples of piezoelectric materials include:

- Quartz

- Berlinite

- Topaz

- Tourmaline

- Cane sugar

- Rochelle salt

A number of ceramic types can also be classified as piezoelectric, such as:

- Barium titanate

- Lead titanate

- PZT

- Lithium niobate

- Lithium tantalite

- Potassium niobate

- Sodium tungstate

Piezoelectric machining helps produce a wide range of applications. For example, soft piezoelectric ceramics build ultrasonic transmitters and receivers, microphones, sound transducers, and other electronic products.

Ceramic Machining Services at Kadco Ceramics

Our primary goal at Kadco Ceramics is to provide clients with high-quality work at reasonable prices. We work hard to ensure that our products meet your specifications down to the smallest detail. We’re committed to providing our customers with the highest level of satisfaction.

At Kadco Ceramics, our engineers and machine operators work with a wide range of materials, such as:

- Alumina

- Ceramic

- Copper

- Garnet

- Piezoceramic materials

- Piezoelectric materials

- Plastic

- Pyrex

- Quartz

- Silicon

- Tungsten

Since 1982, we’ve provided cost-effective engineering and manufacturing solutions to a broad spectrum of clients. We work hard to preserve our reputation as a premier source for ceramic machining services.

If you’d like to learn more about how our ceramic machining services can benefit your company, please reach out to us today.

Thomas Registered Supplier

Thomas Registered Supplier

he original design file within very tight margins.

he original design file within very tight margins.